Assembles and disassembles

quickly, safely,

The automatic anchoring system between straps

allows for quick and safe assembly by just one worker.

Compared to other traditional formwork systems,

this one simplifies partial disassembly

as it does not require any preset order,

offering total freedom to the formworker.

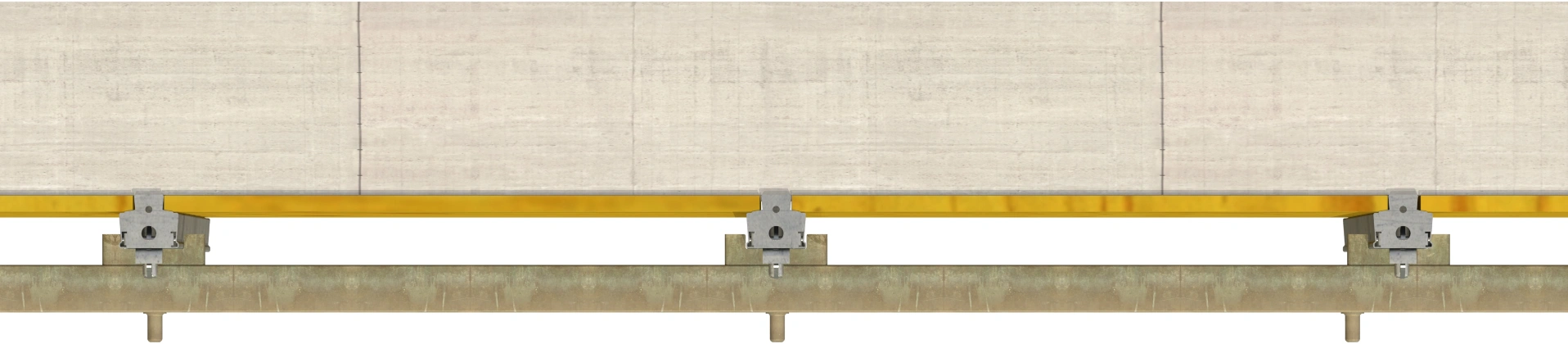

A thoughtfully designed and patented profile section.

The grooved design of the strap profile provides greater rigidity and strength, resulting in an increased lifespan of the material.

These shapes also facilitate the maintenance and cleaning of the material, preventing the accumulation of concrete and optimizing formwork removal to avoid damaging the panel.

Main advantages

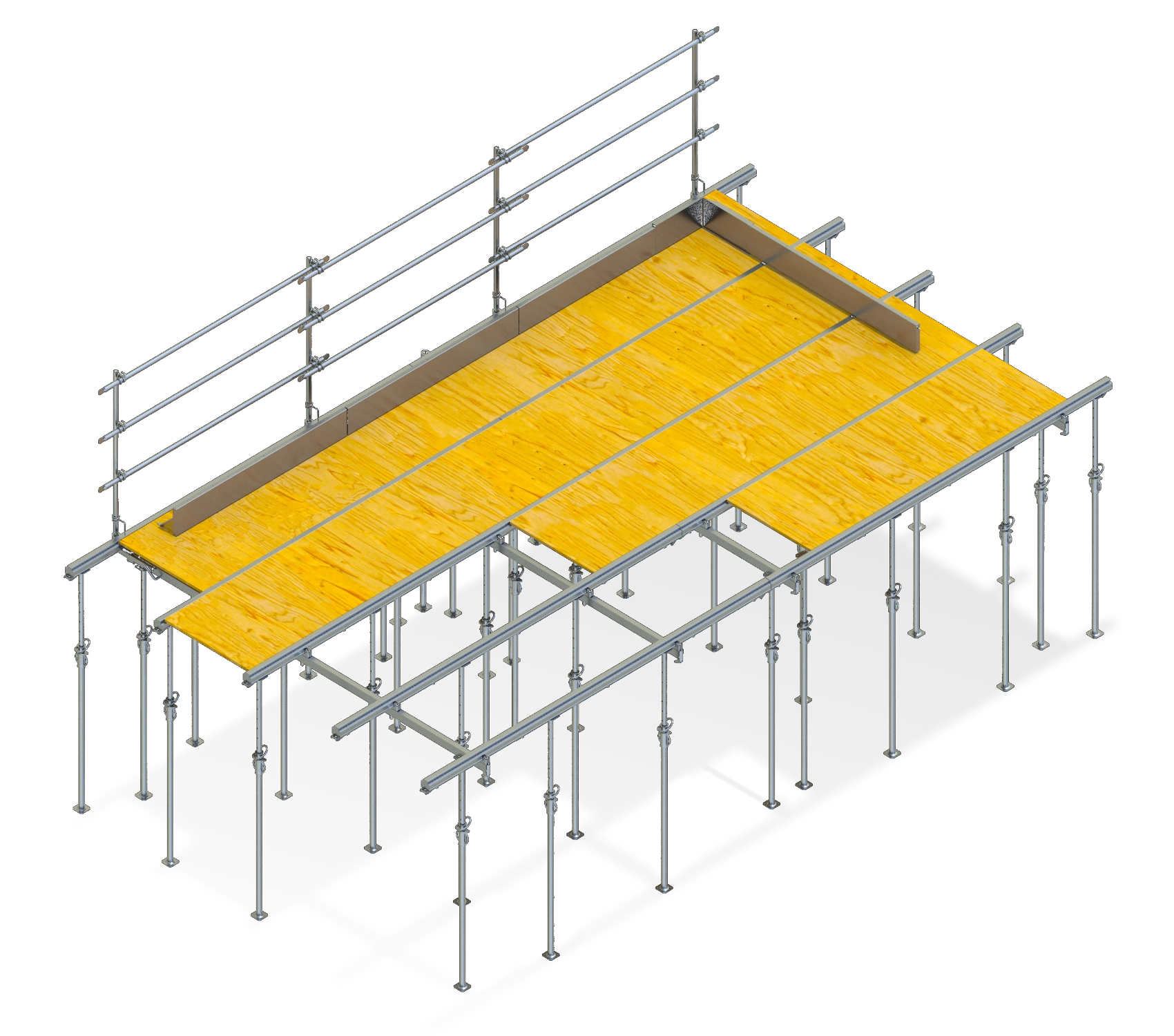

High-productivity system

due to its simplicity and reduced number of elements.

Speed of assembly and disassembly

thanks to its automatic anchoring system.

Variable distance between props

at 1.33m or 1.00m to increase the system's load capacity.

Reduced-format panels to 1.00m

which allow for closer formwork to vertical surfaces.

Placement of panels in both directions

which allows for a proximity to vertical surfaces of up to 0.50m, with an assembly that does not follow a specific order.

Pivoting anchoring solution

that allows for safe formwork removal.

Discover all the details, advantages, and accessories of the STENmetro® system.

Discover all the details, advantages, and accessories of the STENmetro® system.